Manufacturer of Enginnered Products

Enginnered Products

Turbo Offers A Complete Line For Caterpillar G.E.T. System

| J 200 J 220 J 250 | J 300 J 350 J 400 | J 450 J 460 J 550 | J 600 J 700 J 800 | |

|---|---|---|---|---|

| Cat Size | Light Construction | Construction | Heavy Construction | Mining |

| J 200 | J 220 | J 250 | J 300 | J 350 | J 400 | J 450 | J 460 | J 550 | J 600 | J 700 | J 800 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Machine Size (Tons) | 6 | 9 | 11 | 20 | 30 | 40 | 60 | 63 | 80 | 140 | 250 | 300 |

LIGHT CONSTRUCTION MARKET

- For backhoe loaders, mini excavatorsand other compact machines

- Sizes J200, J220 and J250 offer selection of adapters and point shapes to fit all applications

- Both weld-on and bolt-on adapters forwheel loaders.

CONSTRUCTION MARKET

- For mid range wheel loaders and excavators

- Sizes J300,J350 and J400 offer one of the widest selections of points and adapters to service applications from general purpose toextreme service

- Both weld-on and bolt-on adapers for most wheel loaders.

HEAVY CONSTRUCTION MARKET

- For large wheel loaders, excavators and face shovels.

- Sizes J450, J550 and J600 offer a complete range of points and adapters.

- Designed and manufactured to perform in the toughest conditions, from pipeline work in rock to demanding quarry applications.

MINING MARKET

- For wheel loaders, excavators, face shovels and shovel dippers used in mining applications.

- Sizes J700, J800 have a comprehensive offe ring of points and adapters to cover a wide ran ge of heavy duty to extreme duty applications

- All components are designed for maximum strength, reliability and service life to increase productivity and reduce the overall cost of ownership.

Caterpillar Bucket TIP Adapters

Provide Different Performance For Different Jobs

BOTTOM-STRAP WELD-ON ADAPTER

- Provides the largest offset for the most aggressive digging

- Thick bottom strap provides the greatest protection of base edge

- Promotes fast loading; permits easy, complete dumping

- Available for 910 through 992 Loaders.

TWO-STRAP WELD-ON ADAPTER

- Provides best retention in high- impact work.

- For general loading,where adapter etention is a concern

- Protects the base edge well

- Available for 966, 980, 988, 990, 992 and 994 Loaders.

HEAVY DUTY TWO-STRAP WELD-ON ADAPTER

- Thicker to provide increased adap-ter strength

- Weld-groove enlarged for easie-r wel ding, which enhances adapter retention.

- Bottom strap is thicker for longer wear life and greater protection.

- Shouldered to provide rear tip pro tection and improved retention

- Available for 966 through 992 Loaders

FLUSHMOUNT WELD-ON ADAPTER

- Provides smooth bucket footprint, leaving a clean,unrutted work surface.

- Extends tire life.

- Available for 910 through 992 Loaders.

TWO-STRAP WELD-ON

- Provides size-up tip option without increasing thickness

- Stronger, more protection

- Available for 980, 988, 990, 992 and 994 Loaders

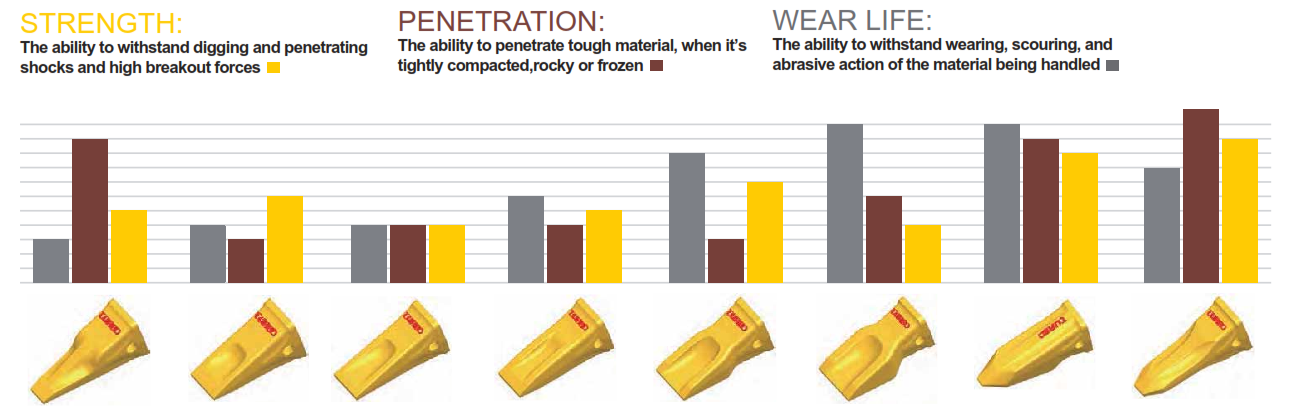

Tip Selection Guide

What To Consider When You're Choosing Tips Bucket

PENETRATION

- Use in densely com pacted material such as clay

- Gives maximum penetration

- Self-sharpening

SHORT

- Use inhigh-impact and pry-out work such as rock

- Extremely strong

LONG

- Use in most general applications where breakage is not a problem

- Extremely strong

HEAVY DUTY LONG

- use in general loading and excavation work.

- Has extended wear Has extended wear strength

HEAVY DUTY LONG LIFE

- life and penetration. As the Heavy Duty

- Long Life tip wears, ease of penetration

HEAVY DUTY PENETRATION

- Use in high-impact, hard-to-penetrate material

- Extended wear life

ROCK CHISEL

- 3 to 5 times more wear life than standard

TIPS FOR SPECIAL APPLICATIONS

UNITOOTH

- A one-piece tip and adapter that bolts to the bucket

- Use in light-to medium-duty work.

CENTER SHARP

- Fitted to central part of the bucket cutting edge.

- Provides maximum gouging and pene-tration capabilities

- Unlike competitive tips, it features a single center rib that keeps tips sharp for life.

WIDE

- Use on excavators to increase capacity in light materials

- Reduces bucket spillage

- Leaves a smoother floor

CORNER SHARP

- Install on bucket corners

- Provides maximum gouging and pene-tration capabilities.

- Can be used on either side of thebucket edge

TWIN SHARP

- Provides more wear material, increased strength, enhanced fracture capabilities.

- Opposite corner tips may be exchanged to prolong wear.